| Brand: | Bermad |

| Category: | Control Valves, Fire Protection Series |

| Size Range: | 50-300mm |

| Connection: | Flanged |

Product Description

The Model FP 450-66 Level Control Valve with Bi-Level Vertical Float is a hydraulically controlled, diaphragm-actuated control valve that controls reservoir filling in response to hydraulic on/off float pressure commands. The Valve opens at pre-set low level and shuts at a pre-set high level.

- Reservoir filling

- Very low supply pressure

- Low noise generation

- Energy cost-critical systems

- Systems with poor water quality

Features and Benefits

- Line-pressure driven – Independent operation

- Bi-Level electric float switch

- On/off service

- Suitable for low-quality water

- One-piece molded elastomeric moving part – No maintenance required

- Dynamically restrained actuation

- Non-slam closing

- Balanced rolling-diaphragm

- High flow capacity

- Very low opening & closing pressure requirement

- External installation

- Easy access to valve & float

- Easy level setting

- Less wear and tear

- In-line serviceable – Easy maintenance

- Flexible design – Easy addition of features

Major Additional Features

- Pressure sustaining – 453-66

- Electric float backup – 450-66-65

- Flow control – 457-66-U

Typical Applications

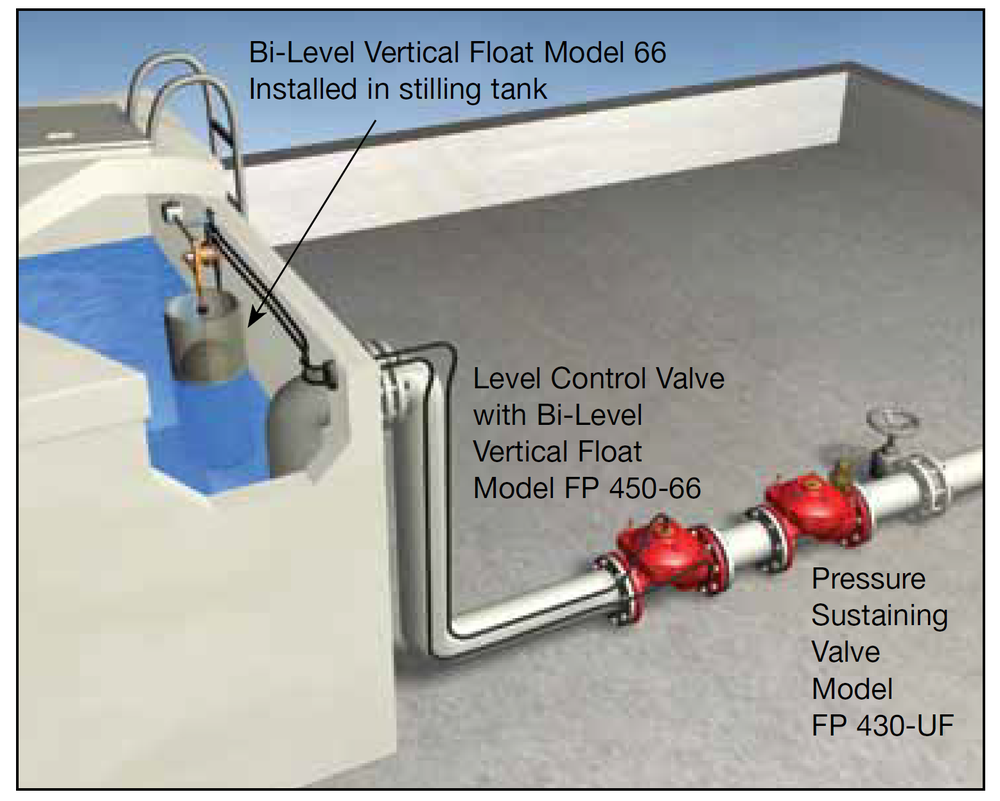

Infrastructure Installation

Rooftop reservoir level control is attained by electric control of the basement pumps according to reservoir level. As the overflow of a rooftop reservoir can cause costly damage, hydraulic backup protection is recommended. The Model FP 450-66 is suited to this function. When open, it presents minimal interference, but when needed, it shuts off securely. To prioritize pressure to upper floor consumers or fire protection systems, install the Model FP 430-UF Pressure Sustaining Valve upstream from the Model FP 450-66.

Bermad - FP-450-66 - Typical Applications - Infrastructure Installation

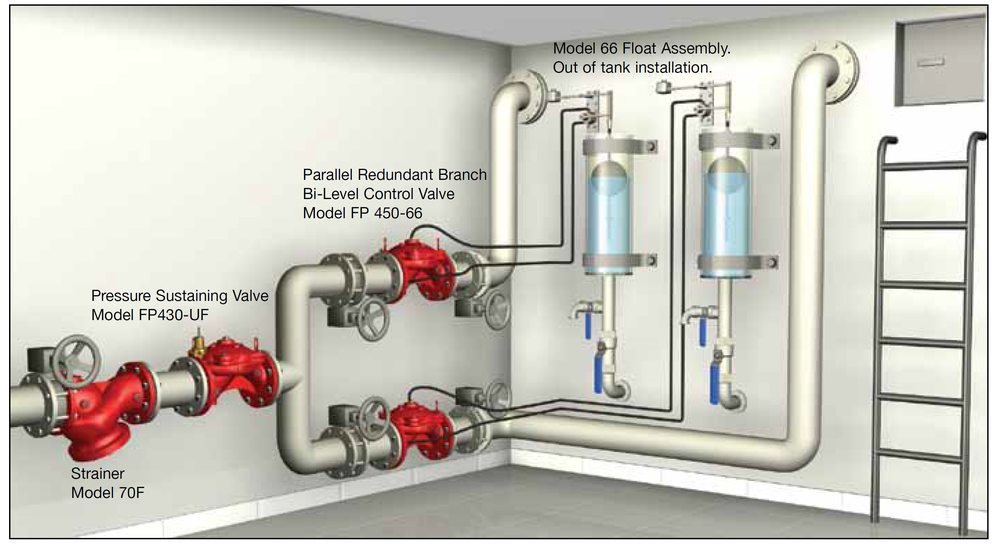

Basement Reservoirs

Basement reservoir design requires consideration of specific issues:

- Supply cut-off is unacceptable.

- Reservoir overflow might damage expensive equipment.

- Noise level and duration should be limited.

- Municipal supply pressure might be low

The Model FP 450-66, as part of a Reservoir Fill-Up system, fulfills these requirements and more.

Bermad - FP-450-66 - Typical Applications - Basement Reservoirs

Technical Data

Operation

The Model FP 450-66 is a float-controlled valve equipped with a 4-way, “last position”, bi-level float pilot assembly. The float [1] slides along the rod [2]. When the float reaches either the adjustable high [3] or low [4] level stoppers, it either pulls the rod assembly down or pushes it up, switching the float pilot's [5] position. When the float is between the adjustable stoppers, the main valve remains in its last position. At

a high level, the float pilot applies pressure to the control chamber [6], powerfully shutting off the main valve. At the low level, the float pilot vents the control chamber, powerfully opening the main valve. For 8” valves and larger, an accelerator [7] quickens valve response

Manufacturers Standard Materials

Main valve body and cover

- Ductile Iron ASTM A-536

Main valve internals

- Stainless Steel & Elastomer

Control Trim System

- Brass control components/accessories

- Stainless Steel 316 tubing & fittings

Elastomers

- Polyamide fabric reinforced Polyisoprene, NR

Coating

- Electrostatic Powder Coating Polyester, Red (RAL 3002)

Optional Materials

Main valve body

- Carbon Steel ASTM A-216 WCB

- Stainless Steel 316

- Ni-Al-Bronze ASTM B-148

Control Trim

- Stainless Steel 316

- Monel® and Al-Bronze

- Hastelloy C-276

Elastomers

- NBR

- EPDM

Coating

- High Build Epoxy Fusion-Bonded with UV Protection, Anti-Corrosion

Float Data

Standard Materials:

- Pilot body: Brass

- Seals: NBR (Buna N)

- Internals: Stainless Steel & Brass

- Lever system: Brass

- Float: Plastic

- Float rod: Stainless Steel

- Base plate: Fusion bonded epoxy coated Stainless Steel

Optional materials:

- Stainless Steel metal parts and float, FPM (Viton®) seals

General Information:

- Minimum level differential: 15 cm (6”)

- Maximum level differential: 54 cm (21”)

- Each extension rod adds 56 cm (22”), and one extension rod supplied

- Extra counterweight required if second extension rod used see BERMAD float installation recommendations

If inlet pressure is below 0.7 bar (10 psi) or above 10 bar (150 psi), consult Deeco.

Main Valve

Connection Standard

- Flanged: ANSI B16.42 (Ductile Iron), B16.5 (Steel & Stainless Steel), B16.24 (Bronze) ISO PN16

Water Temperature

- 0.5 – 50°C (33 – 122°F)

Available Sizes

- Globe: 1½, 2, 2½, 3, 4, 6, 8, 10 & 12”

- Angle: 2, 3 & 4”

Pressure Rating

- Max. inlet: 250 psi (17 bar)

Technical Specifications

Engineering Specifications

The Level Control Valve shall hydraulically open at pre-set low level, and shut at pre-set high level. Main Valve: The main valve shall be an elastomeric-type globe (or angle) valve with a rolling diaphragm. The valve shall have an unobstructed flow path, with no stem guide or supporting ribs. The body and cover shall be ductile iron. All external bolts and nuts shall be of stainless steel 316. All valve components shall be accessible and serviceable without removing the valve from the pipeline. Actuation: Valve actuation shall be accomplished by a fully peripherally supported, one-piece balanced rolling diaphragm, vulcanized with a rugged radial seal disk. The diaphragm assembly shall be the only moving part. Quality Assurance: The valve manufacturer shall be certified according to the ISO 9000 and 9001 Quality Assurance Standards.

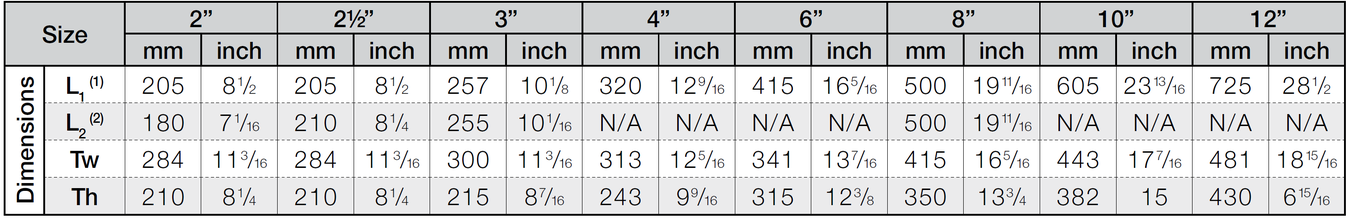

Dimensions and Weights

Bermad - FP-450-66 - Dimensions and Weights

Due to the wide range of options and criteria for correct model selection, pricing and configuration are available on application only.

Please contact us for more information.