| Brand: | Zurn Wilkins |

| Category: | Backflow Prevention, 375 Series |

| Size Range: | 65-250mm |

| Other Sizes: | |

| Connection: | Flanged AS2129 Table D/E |

Product Description

The Zurn Wilkins 375 Reduced Pressure Principle Backflow Preventer provides high-hazard protection for all applications. The flanged, epoxy-coated ductile iron body is available with multiple shut-off valve options for installation versatility.

Features and Benefits

- Short lay length for small space installation.

- NRS, OS&Y, or Butterfly shut-off valves are available.

- Available in flanged, grooved, or grooved X flanged end connections for installation versatility.

- Ideal for any backflow replacement.

- Utilizes Zurn Wilkins low headloss Compound Check for reliable and superior performance.

- No threads or taps in the body or cover, eliminating exposure to corrosion.

- Single access cover reduces downtime.

- No threads or taps in the body or cover, eliminating exposure to corrosion.

Typical Application

Designed for installation on potable water lines to protect against both back siphonage and backpressure of contaminated water into the potable water supply. Reduced Pressure Zone Device Assembly shall provide protection where a potential health hazard exists. (High Hazard).

Zurn Wilkins - 375L - Customer Installation

Standards Compliance

- Australian Watermark and Standards Mark

- UL Classified

- FM Approved

Technical Data

Operating Parameters

- Max. Working Water Pressure: 1200kPa

- Max. Working Temperature: 60°C

- Hydrostatic Test Pressure: 2400kPa

- End Connections: Flanges to AS2129

Materials

- Main Valve Body Ductile Iron ASTM A536 Grade 4

- Access Covers Ductile Iron ASTM A536 Grade 4

- Coatings Fusion Epoxy

- Fasteners Stainless Steel 300 Series

- Internals Stainless Steel 300 Series, Noryl™

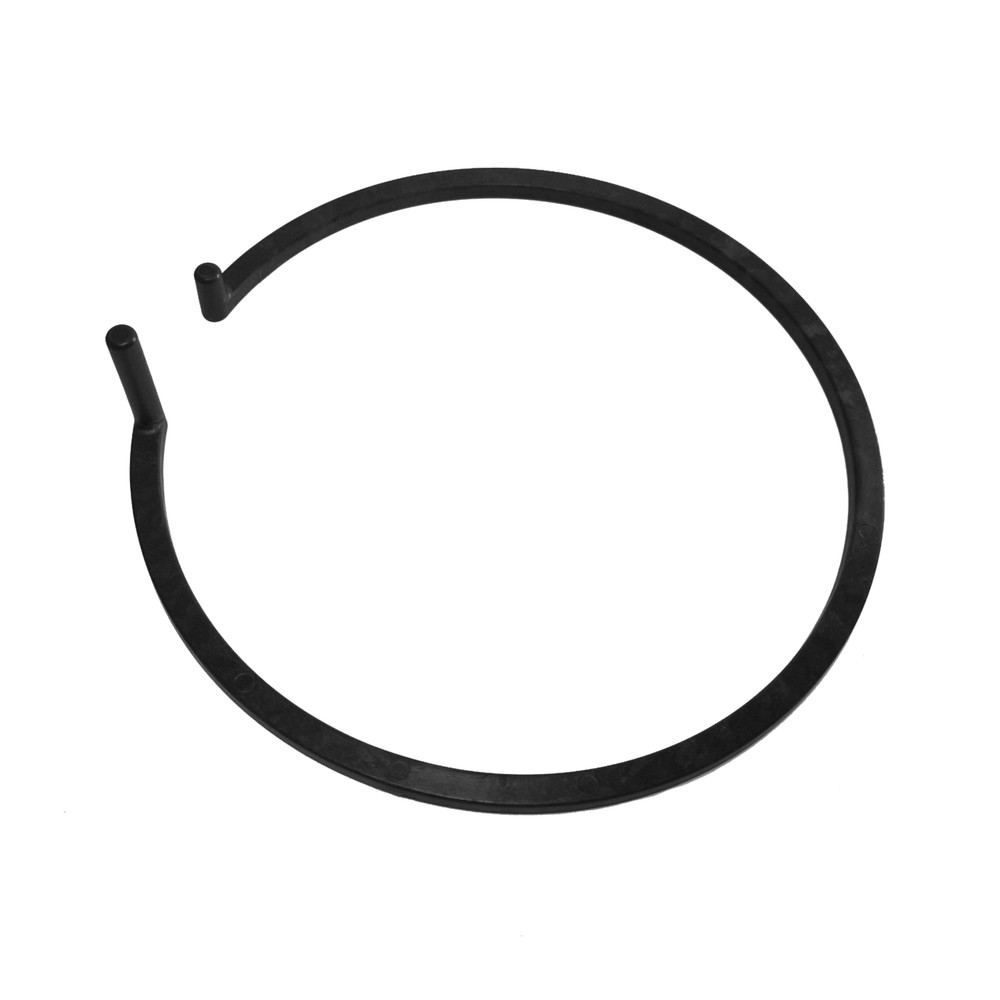

- Seal Ring EPDM

- O-ring Buna Nitrile

- Springs Stainless Steel 300 Series

- Sensing Line Stainless Steel, Braided Hose

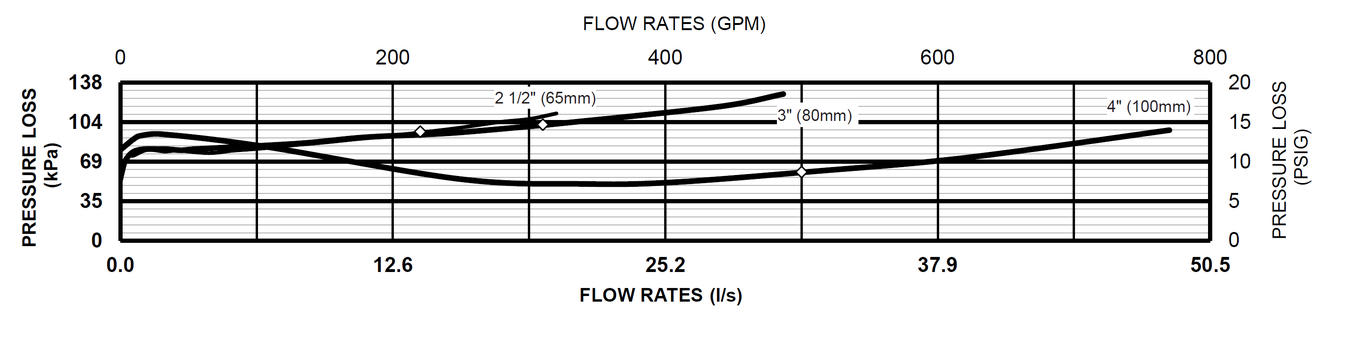

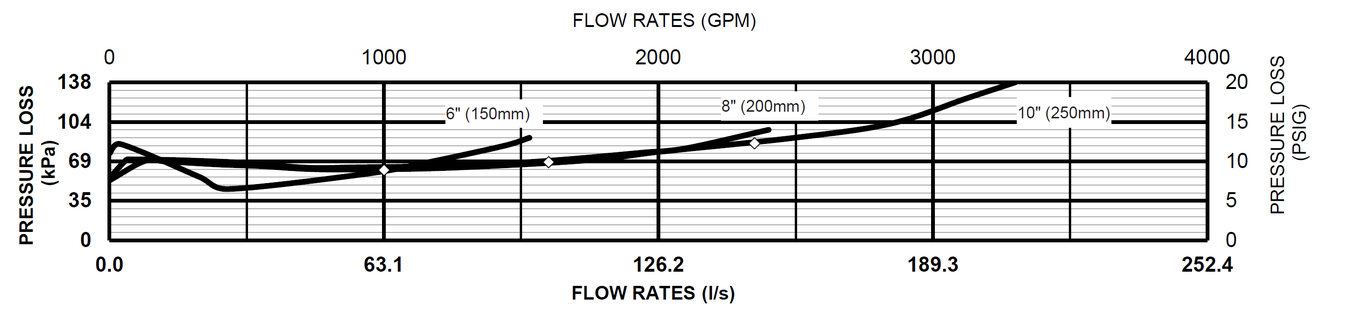

Flow Characteristics

MODEL 375 RPZ 65mm, 80mm & 100mm (STANDARD & METRIC)

Zurn Wilkins - 375L-65mm, 80mm,100mm - Flow Rates

MODEL 375 RPZ 150mm, 200mm, 250mm (STANDARD & METRIC)

Zurn Wilkins - 375L-10mm, 200mm, 250mm - Flow Rates

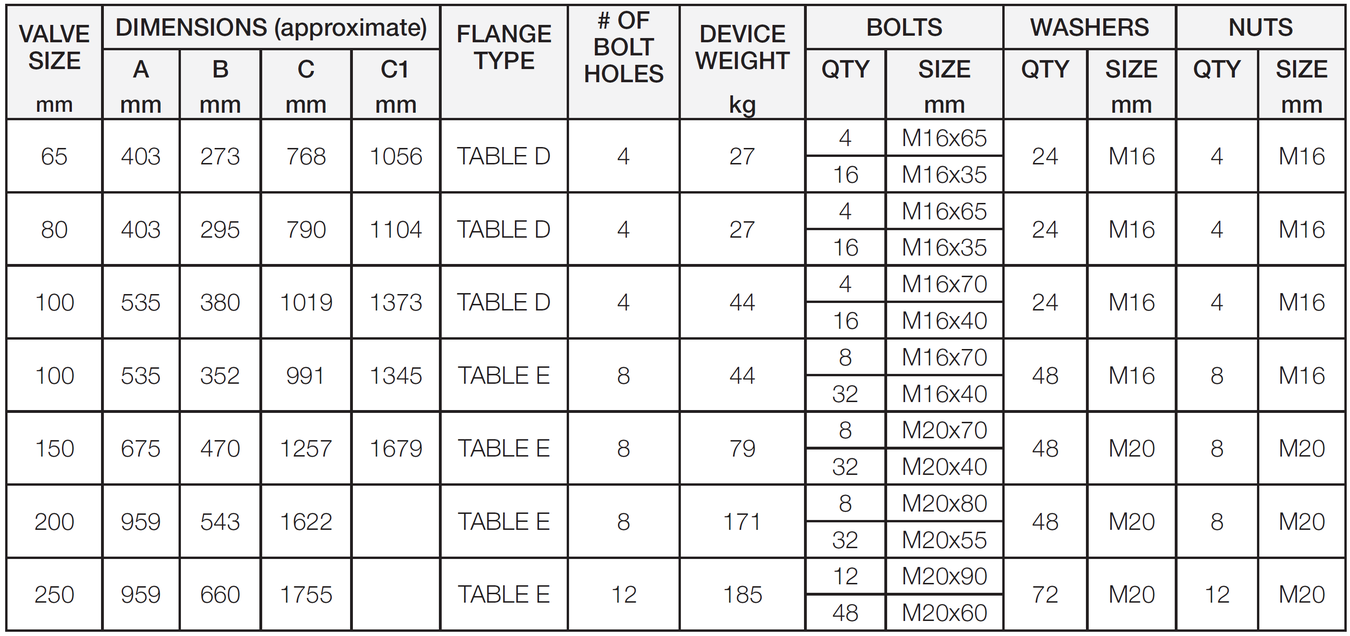

Technical Specifications

Dimensional Drawing

Zurn Wilins - 375L - 65,80,100,150mm - Butterfly Valve

Dimensions and Weights (do not include pkg.)

Typical Installation

Local codes shall govern installation requirements. To be installed in accordance with the manufacturers’ instructions and the latest edition of the Plumbing Code of Australia and/or AS/NZS 3500. Unless otherwise specified, the assembly shall be mounted at a minimum of 12" (305mm) and a maximum of 30" (762mm) above adequate drains with sufficient side clearance for testing and maintenance. The installation shall be made so that no part of the unit can be submerged.

Zurn Wilins - 375L - Typical Installation

Zurn Wilkins - 375L Series - Backflow Preventer - Repair Kits

| Product Code | Size | Description |

|---|---|---|

RK212-350 |

65-80mm |

Model 350/375L - Repair Kit - Check Rubbers only (Suits Ductile and Stainless) |

RK4-350 |

100mm |

Model 350/375L - Repair Kit - Check Rubbers only (Suits Ductile and Stainless) |

RK6-350 |

150mm |

Model 350/375L - Repair Kit - Check Rubbers only (Suits Ductile and Stainless) |

RK8-350 |

200-300mm |

Model 350/375L - Repair Kit - Check Rubbers only (Suits Ductile and Stainless) |

RK212-375 |

65-150mm |

Model 375L - Relief Only - Repair Kit Complete (Suits Ductile and Stainless) |

RK212-375R |

65-150mm |

Model 375L - Relief Rubber Only - Repair Kit (Suits Ductile and Stainless) |

RK8-375 |

200-250mm |

Model 375L - Relief Only - Repair Kit Complete (Suits Ductile and Stainless) |

RK8-375R |

200-250mm |

Model 375L - Relief Rubber Only - Repair Kit (Suits Ductile and Stainless) |

Model 350/375L - Repair Kit - Check Rubbers only (Suits Ductile and Stainless)

| Pos. | Description | Qty |

|---|---|---|

1 |

Seal Ring for Check Assembly #1 |

1 |

2 |

Seal Ring for Check Assembly #2 |

1 |

3 |

O-Rings for Poppet Bolt |

2 |

4 |

O-Ring for #1 Check |

1 |

5 |

O-Ring for #2 Check |

1 |

Model 350/375L - Repair Kit - Check Rubbers only (Suits Ductile and Stainless)

| Pos. | Description | Qty | |

|---|---|---|---|

1 |

Seal Ring for Check Assembly #1 |

1 |

|

2 |

Seal Ring for Check Assembly #2 |

1 |

|

3 |

O-Rings for Poppet Belt |

8 |

|

4 |

O-Rings for Checks |

2 |

|

5 |

O-Rings for AST valves |

2 |

|

Model 350/375L - Repair Kit - Check Rubbers only (Suits Ductile and Stainless)

| Pos. | Description | Qty | |

|---|---|---|---|

1 |

O-Ring for #1 Check |

1 |

|

2 |

O-Ring for #2 Check |

1 |

|

3 |

O-Rings for Poppet Bolt |

8 |

|

4 |

Seal Ring for Check Assembly #1 |

1 |

|

5 |

Seal Ring for Check Assembly #2 |

1 |

|

6 |

Lubricant |

2 |

Model 350/375L - Repair Kit - Check Rubbers only (Suits Ductile and Stainless)

| Pos. | Description | Qty | |

|---|---|---|---|

1 |

O-Ring for #1 Check |

1 |

|

2 |

O-Ring for #2 Check |

1 |

|

3 |

O-Rings for Poppet Bolt |

8 |

|

4 |

Seal Ring for Check Assembly #1 |

1 |

|

5 |

Seal Ring for Check Assembly #2 |

1 |

|

Model 375L - Relief Only - Repair Kit Complete (Suits Ductile and Stainless)

| Pos. | Description | Qty | |

|---|---|---|---|

1 |

Diaphragm |

1 |

|

2 |

Relief Valve Spring |

1 |

|

3 |

O-Ring for Upper Plunger |

1 |

|

4 |

Seal Ring for Relief Valve |

1 |

|

5 |

O-Ring for Seat |

1 |

|

6 |

O-Ring for Relief Valve |

1 |

|

7 |

Lubricant |

1 |

Model 375L - Relief Rubber Only - Repair Kit (Suits Ductile and Stainless)

| Pos. | Description | Qty | |

|---|---|---|---|

1 |

Diaphragm |

1 |

|

2 |

Seal Ring for Relief Valve |

1 |

|

3 |

O-Ring for Upper Plunger |

1 |

|

4 |

O-Ring for Seat |

1 |

|

5 |

O-Ring for Relief Valve |

1 |

|

6 |

Lubricant |

1 |

Model 375L - Relief Only Repair Kit Complete (Suits Ductile and Stainless)

| Pos. | Description | Qty | |

|---|---|---|---|

1 |

Relief Valve Spring |

1 |

|

2 |

Seal Ring for Relief Valve |

1 |

|

3 |

O-Ring for Relief Valve Seat |

1 |

|

4 |

O-Ring for Relief Valve |

1 |

|

5 |

Diaphragm |

1 |

|

6 |

O-Ring for Upper Plunger |

1 |

Model 375L - Relief Rubber Only - Repair Kit (Suits Ductile and Stainless)

| Pos. | Description | Qty | |

|---|---|---|---|

1 |

Diaphragm |

1 |

|

2 |

Seal Ring for Relief Valve |

1 |

|

3 |

O-Ring for Relief Valve Seat |

1 |

|

4 |

O-Ring for Relief Valve |

1 |

|

5 |

O-Ring for Upper Plunger |

1 |

|

6 |

Lubricant |

1 |

Zurn Wilkins - 375L Series - Backflow Preventer - Spare Parts

Check Assembly

| Pos. | Product Code | Size | Description |

|---|---|---|---|

1 |

3707-300 |

65-80mm |

Check Assembly #1 |

2 |

3507-300A |

65-80mm |

Check Assembly #2 |

3 |

3709-300 |

100mm |

Check Assembly #1 |

4 |

3509-300B |

100mm |

Check Assembly #2 |

5 |

3710-300 |

150mm |

Check Assembly #1 |

6 |

3510-300B |

150mm |

Check Assembly #2 |

7 |

3712-300 |

200-300mm |

Check Assembly #1 |

8 |

3512-300B |

200-300mm |

Check Assembly #2 |

Check Retainers

1. 3507-14F

2. 3507-14G

3. 3509-14B

4. 3509-140

5. 3510-14B

6. 3510-140

| Pos. | Product Code | Size | Description |

|---|---|---|---|

1 |

3507-14F |

65-80mm |

Seat Retainer #1 Check |

2 |

3507-14G |

65-80mm |

Seat Retainer #2 Check |

3 |

3509-14B |

100mm |

Seat Retainer #1 Check |

4 |

3509-140 |

100mm |

Seat Retainer #2 Check |

5 |

3510-14B |

150mm |

Seat Retainer #1 Check |

6 |

3510-140 |

150mm |

Seat Retainer #2 Check |

Zurn Wilkins - 375L Series - Backflow Preventer - Device Only

High Hazard, High-Performance, Low Head Loss Backflow Preventer

Zurn Wilkins - 375L100

| Product Code | Size | Description |

|---|---|---|

375L065 |

65mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 - Flanged to AS2129 Table D/E |

375L080 |

80mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 - Flanged to AS2129 Table D/E |

375L100 |

100mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 - Flanged to AS2129 Table D |

375L150 |

150mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 - Flanged to AS2129 Table D/E |

375L200 |

200mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 - Flanged to AS2129 Table D/E |

375L250 |

250mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 - Flanged to AS2129 Table D |

Note: Strainer and Valves are supplied loose, not including dressing sets or assembly

Zurn Wilkins - 375L100+S

| Product Code | Size | Description |

|---|---|---|

375L065+S |

65mm |

High Hazard, Reduce Pressure Zone Backflow Preventer - Model 375 + Y Strainer - Flanged to AS2129 Table D/E |

375L080+S |

80mm |

High Hazard, Reduce Pressure Zone Backflow Preventer - Model 375 + Y Strainer - Flanged to AS2129 Table D/E |

375L100+S |

100mm |

High Hazard, Reduce Pressure Zone Backflow Preventer - Model 375 + Y Strainer - Flanged to AS2129 Table D |

375L150+S |

150mm |

High Hazard, Reduce Pressure Zone Backflow Preventer - Model 375 + Y Strainer - Flanged to AS2129 Table D/E |

375L200+S |

200mm |

High Hazard, Reduce Pressure Zone Backflow Preventer - Model 375 + Y Strainer - Flanged to AS2129 Table D/E |

375L250+S |

250mm |

High Hazard, Reduce Pressure Zone Backflow Preventer - Model 375 + Y Strainer - Flanged to AS2129 Table D |

Note: Strainer and Valves are supplied loose, not including dressing sets or assembly

Zurn Wilkins - 375L100+SV

| Product Code | Size | Description |

|---|---|---|

375L065+SV |

65mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Gate Valves - Flanged to AS2129 Table D/E |

375L080+SV |

80mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Gate Valves - Flanged to AS2129 Table D/E |

375L100+SV |

100mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Gate Valves - Flanged to AS2129 Table D |

375L150+SV |

150mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Gate Valves - Flanged to AS2129 Table D/E |

375L200+SV |

200mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Gate Valves - Flanged to AS2129 Table D/E |

375L250+SV |

250mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Gate Valves - Flanged to AS2129 Table D |

Note: Strainer and Valves are supplied loose, not including dressing sets or assembly

Zurn Wilkins - 375L100+SBV

| Product Code | Size | Description |

|---|---|---|

375L065+SBV |

65mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Butterfly Valves - Flanged to AS2129 Table D/E |

375L080+SBV |

80mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Butterfly Valves - Flanged to AS2129 Table D/E |

375L100+SBV |

100mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Butterfly Valves - Flanged to AS2129 Table D |

375L150+SBV |

150mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Butterfly Valves - Flanged to AS2129 Table D/E |

375L200+SBV |

200mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Butterfly Valves - Flanged to AS2129 Table D/E |

375L250+SBV |

250mm |

High Hazard, Reduced Pressure Zone Backflow Preventer - Model 375 + Y Strainer + Butterfly Valves - Flanged to AS2129 Table D |

Zurn Wilkins - 375SPD Series, Stainless Steel - Backflow Preventer

High Hazard, High-Performance, Low Head Loss, Corrosion Resistant Backflow Preventer

Zurn Wilkins - 375SPD100

| Product Code | Size | Description |

|---|---|---|

375SPD100 |

100mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375SPD - Flanged to AS2129 Table D |

375SPD150 |

150mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375SPD - Flanged to AS2129 Table D/E |

Note: Strainer and Valves are supplied loose, not including dressing sets or assembly

Zurn Wilkins - 375SPD100+S

Zurn Wilkins - 375SPD100+SV

Zurn Wilkins - 375100+SBV

| Product Code | Size | Description |

|---|---|---|

375SPD100+S |

100mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375SPD + Y Strainer - Flanged to AS2129 Table D |

375SPD150+S |

150mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375SPD + Y Strainer - Flanged to AS2129 Table D/E |

375SPD100+SV |

100mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375SPD + Y Strainer + Gate Valves - Flanged to AS2129 Table D |

375SPD150+SV |

150mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375SPD + Y Strainer + Gate Valves - Flanged to AS2129 Table D/E |

375SPD100+SBV |

100mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375SPD + Y Strainer + Butterfly Valves - Flanged to AS2129 Table D |

375SPD150+SBV |

150mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375SPD + Y Strainer + Butterfly Valves - Flanged to AS2129 Table D/E |

Zurn Wilkins - 375DAL Series, Ductile Iron - Reduced Pressure Detector Assembly

Testable double-check assembly with 20mm Sensus water meter and testable double-check assembly bypass with lockable ball valves.

| Product Code | Size | Description |

|---|---|---|

375DAL050 |

50mm |

Backflow Preventer Assembly and Detector Check - BSP Only |

375DAL065 |

65mm |

Backflow Preventer Assembly and Detector Check - Ductile Iron, Flanged Only |

375DAL080 |

80mm |

Backflow Preventer Assembly and Detector Check - Ductile Iron, Flanged Only |

375DAL100 |

100mm |

Backflow Preventer Assembly and Detector Check - Ductile Iron, Flanged Only |

375DAL150 |

150mm |

Backflow Preventer Assembly and Detector Check - Ductile Iron, Flanged Only |

375DAL200 |

200mm |

Backflow Preventer Assembly and Detector Check - Ductile Iron, Flanged Only |

375DAL250 |

250mm |

Backflow Preventer Assembly and Detector Check - Ductile Iron, Flanged Only |

Zurn Wilkins - 375ASTL Series, Stainless Steel - Backflow Preventer

High Hazard, High-Performance, Low-Head Loss, Corrosion Resistant Backflow Preventer

Zurn Wilkins - 375ASTL100

| Product Code | Size | Description |

|---|---|---|

375ASTL100 |

100mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375ASTL - Grooved |

375ASTL150 |

150mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375ASTL - Grooved |

375ASTL200 |

200mm |

High Hazard, Stainless Steel, Double Check Backflow Preventer - Model 375ASTL - Grooved |

Available in AS4087-2011 PN16 Flange/Flanges or Grooved Connections

Zurn Wilkins - 375ASTDAL Series, Stainless Steel - Reduced Pressure Detector Assembly

Testable double-check assembly with 20mm Sensus water meter and testable double-check assembly bypass with lockable ball valves.

New Zealand Insurance Council approved for fire lines.

Zurn Wilkins - 375ASTDAL100

| Product Code | Size | Description |

|---|---|---|

375ASTDAL100 |

100mm |

Backflow Preventer Assembly and Detector Check - Stainless Steel, Grooved |

375ASTDAL150 |

150mm |

Backflow Preventer Assembly and Detector Check - Stainless Steel, Grooved |

375ASTDAL200 |

200mm |

Backflow Preventer Assembly and Detector Check - Stainless Steel, Grooved |

Available in AS4087-2011 PN16 Flange/Flanges or Grooved Connections

Additional Accessories

Epoxy Coated with Stainless Steel Screen. Flange/Flange - AS2129 Table D

Zurn Wilkins - YS100

| Prooduct Code | Size | Description |

|---|---|---|

YS065 |

65mm |

Flanged Y Strainer, FBE Coated, Flange/Flange - AS2129 Table D/E |

YS080 |

80mm |

Flanged Y Strainer, FBE Coated, Flange/Flange - AS2129 Table D/E |

YS100 |

100mm |

Flanged Y Strainer, FBE Coated, Flange/Flange - AS2129 Table D |

YS150 |

150mm |

Flanged Y Strainer, FBE Coated, Flange/Flange - AS2129 Table D/E |

YS200 |

200mm |

Flanged Y Strainer, FBE Coated, Flange/Flange - AS2129 Table D/E |

YS250 |

250mm |

Flanged Y Strainer, FBE Coated, Flange/Flange - AS2129 Table D/E |

NRS100

| Prooduct Code | Size | Description |

|---|---|---|

NRS065 |

65mm |

Isolating Gate Valve c/w Handle Wheel and Non-Rising Stem. Full Bore AS4087 PN16. Flange / Flange |

NRS080 |

80mm |

Isolating Gate Valve c/w Handle Wheel and Non-Rising Stem. Full Bore AS4087 PN16. Flange / Flange |

NRS100 |

100mm |

Isolating Gate Valve c/w Handle Wheel and Non-Rising Stem. Full Bore AS4087 PN16. Flange / Flange |

NRS150 |

150mm |

Isolating Gate Valve c/w Handle Wheel and Non-Rising Stem. Full Bore AS4087 PN16. Flange / Flange |

NRS200 |

200mm |

Isolating Gate Valve c/w Handle Wheel and Non-Rising Stem. Full Bore AS4087 PN16. Flange / Flange |

NRS250 |

250mm |

Isolating Gate Valve c/w Handle Wheel and Non-Rising Stem. Full Bore AS4087 PN16. Flange / Flange |

BV100

| Prooduct Code | Size | Description |

|---|---|---|

BV050 |

50mm |

Wafer (Universal) Epoxy Coated CI Body, SS316 Disc, EPDM Seat, c/w Notched Lever Handle |

BV065 |

65mm |

Wafer (Universal) Epoxy Coated CI Body, SS316 Disc, EPDM Seat, c/w Notched Lever Handle |

BV080 |

80mm |

Wafer (Universal) Epoxy Coated CI Body, SS316 Disc, EPDM Seat, c/w Notched Lever Handle |

BV100 |

100mm |

Wafer (Universal) Epoxy Coated CI Body, SS316 Disc, EPDM Seat, c/w Notched Lever Handle |

BV150 |

150mm |

Wafer (Universal) Epoxy Coated CI Body, SS316 Disc, EPDM Seat, c/w Notched Lever Handle |

BV200 |

200mm |

Wafer (Universal) Epoxy Coated CI Body, SS316 Disc, EPDM Seat, c/w Notched Lever Handle |

BV250 |

250mm |

Wafer (Universal) Epoxy Coated CI Body, SS316 Disc, EPDM Seat, c/w Notched Lever Handle |

RSM100

| Prooduct Code | Size | Description |

|---|---|---|

RSM100 |

100mm |

Gate Valve - Table D/E Flange Type or Grooved - with Tamper Switch |

RSM150 |

150mm |

Gate Valve - Table D/E Flange Type or Grooved - with Tamper Switch |

RSM200 |

200mm |

Gate Valve - Table D/E Flange Type or Grooved - with Tamper Switch |

SBOV100 |

100mm |

Grooved Butterfly Valve with Tamper Switch |

SBOV150 |

150mm |

Grooved Butterfly Valve with Tamper Switch |

SBOV200 |

200mm |

Grooved Butterfly Valve with Tamper Switch |

100WS2000

| Prooduct Code | Size | Description |

|---|---|---|

100WS2000 |

100mm |

Welding Strainer 500-2,000 l/m |

150WS4000 |

150mm |

Welding Strainer ~4,000 l/m |

150WS4500 |

150mm |

Welding Strainer ~4,500 l/m |

150WS5000 |

150mm |

Welding Strainer 5,000 l/m |

200WS6000 |

200mm |

Welding Strainer ~6,000 l/m |

200WS6500 |

200mm |

Welding Strainer 6,500 l/m |

200WS7000 |

200mm |

Welding Strainer 7,000 l/m |

200WS7500 |

200mm |

Welding Strainer 7,500 l/m |

To suit 350/375 ASTL Grooved backflow devices and grooved gate valves, butterfly valves or welding strainer.

RGGF100

| Prooduct Code | Size | Description |

|---|---|---|

GC100 |

100mm |

Roll Groove / Roll Groove Rigid Coupler - Galvanised |

GC150 |

150mm |

Roll Groove / Roll Groove Rigid Coupler - Galvanised |

GC200 |

200mm |

Roll Groove / Roll Groove Rigid Coupler - Galvanised |

RGFA100 |

100mm |

Roll Groove Fixed Flange Adaptor - Table E - Galvanised |

RGFA150 |

150mm |

Roll Groove Fixed Flange Adaptor - Table E - Galvanised |

RGFA200 |

200mm |

Roll Groove Fixed Flange Adaptor - Table E - Galvanised |

RGGF100 |

100mm |

Roll Groove Hinged Flange Adaptor - Table E - Galvanised |

RGGF150 |

150mm |

Roll Groove Hinged Flange Adaptor - Table E - Galvanised |

RGGF200 |

200mm |

Roll Groove Hinged Flange Adaptor - Table E - Galvanised |