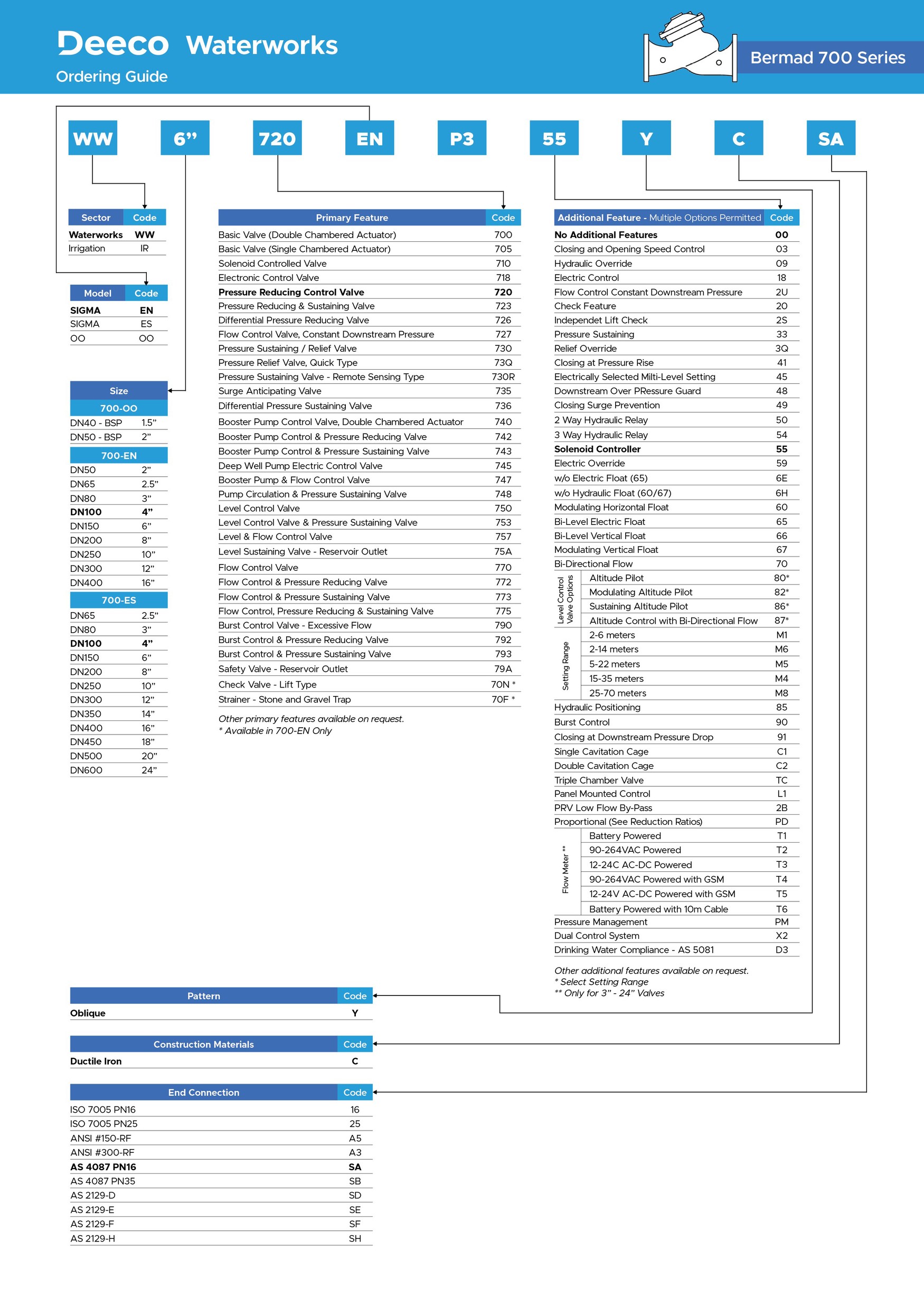

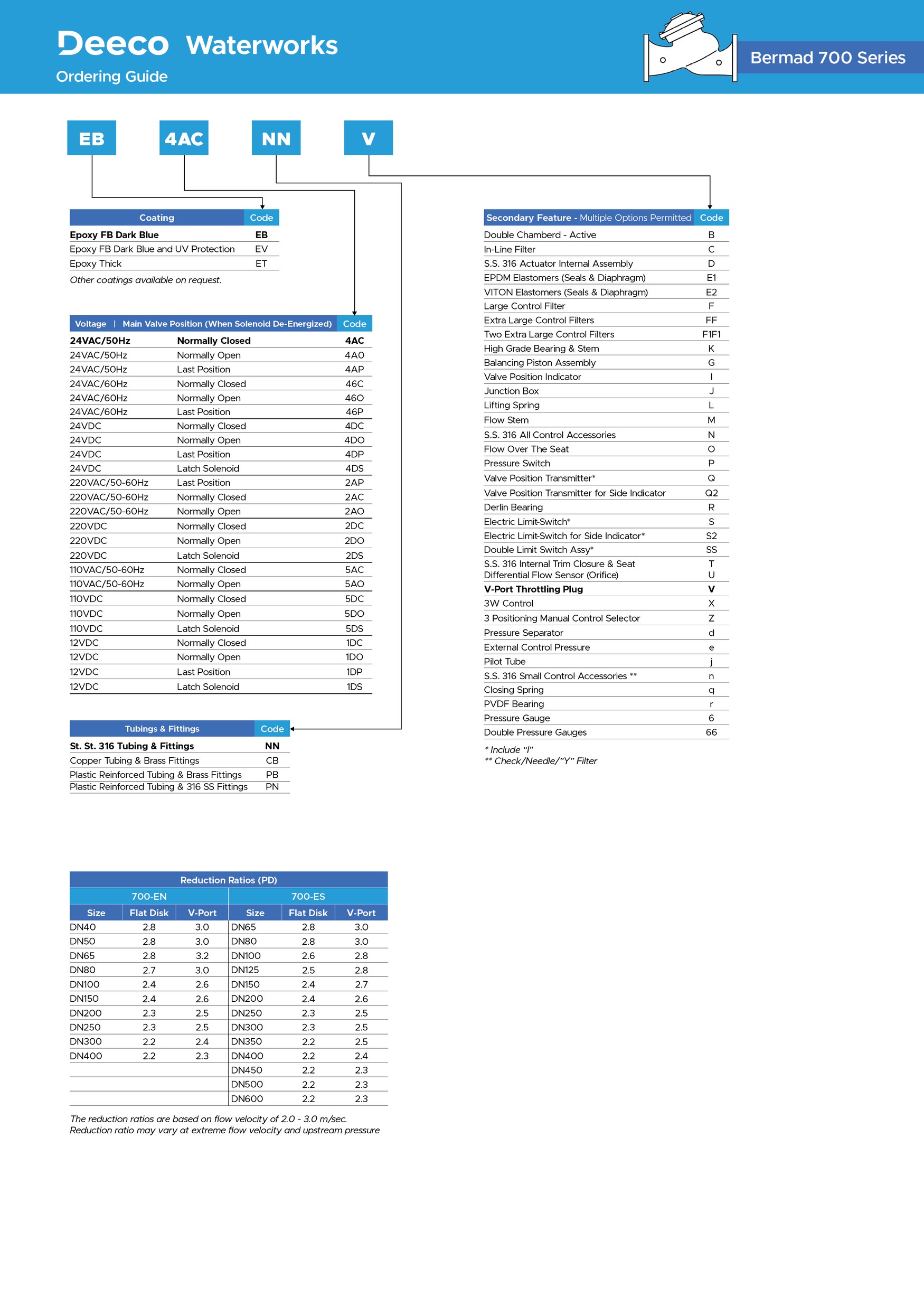

| Brand: | Bermad |

| Category: | Control Valves, 700 Series |

| Size Range: | 50-600mm |

| Connection: | EN: 50-400mm - Flanged ES: 65-600mm - Flanged |

| Engineering Data: |

Product Description

Hydraulically operated flow control valve that maintains pre-set maximum flow, regardless of fluctuating demand or varying system pressure. BERMAD 700 SIGMA EN/ES series valves are hydraulic, oblique pattern, globe valves with a raised seat assembly and double chamber unitized actuator, that can be disassembled from the body as a separate integral unit. The valve's hydrodynamic body is designed for an unobstructed flow path and provides excellent and highly effective modulation capacity for high differential pressure applications. The valves are available in the standard configuration or with an Independent Check Feature code “2S”. The 700 SIGMA EN/ES Valves operate under difficult operation conditions with minimal cavitation and noise. They meet the size and dimensions requirements of various standards.

Features and Benefits

- Designed to - stand up to the toughest conditions

- Excellent anti-cavitation properties

- Wide flow range

- High stability and accuracy

- Drip tight sealing

- Double chamber design

- Moderated valve reaction

- Protected diaphragm

- Optional operation in very low pressure

- Moderated closing curve

- Flexible design - Easy addition of features

- Obstacle-free flow pass

- V-Port Throttling Plug (Optional) - Very stable at low flow

- Compatible with various standards

- High-quality materials

- In-line serviceable - Easy maintenance

Major Additional Features

- Solenoid control – 770-55-U

- Solenoid control & check feature – 770-25-U

- High sensitivity pilot – 770-12-U

- Pressure Reducing – 772-U

- Level & flow control valve – 757-U

- Pump & flow control valve – 747-U

- Pump circulation & flow control valve – 749-U

- Electronic control valve – 718-03

- Independent Check Feature – 770-U-2S

Typical Installation

Bermad - Model 770 - Typical Installation

Technical Data

Operation

This drawing refers to 40-200 mm sized valves only. For other sizes please refer to the Model’s IOM.

Main Valve

Valve Patterns: “Y” (Globe)

Size Range: 50-600mm

Pressure Rating: 16 bar - with higher pressure options available.

End Connections:

EN: 50-400mm - Flanged

ES: 65-600mm - Flanged

Plug Types: Flat disc, V-port, Cavitation cage

Temperature Rating: 60°C, for Coldwater applications

Optional higher temperature: Available on request

Standard Materials:

Body & actuator: Ductile Iron

Bolts, nuts & studs: Stainless Steel

Internals: Stainless Steel, Tin Bronze & Coated Steel

Diaphragm: Fabric-reinforced synthetic rubber

Seals: Synthetic rubber

Coating: Dark blue Fusion bonded epoxy

Control System

Standard Materials:

Accessories: Stainless Steel, Bronze & Brass

Tubing: Stainless Steel or Copper

Fittings: Stainless Steel or Brass

Pilot Standard Materials:

Body: Stainless Steel, Bronze or Brass

Elastomers: Synthetic Rubber

Spring: Stainless Steel

Internals: Stainless Steel

Pilot Options:

Various pilots and calibration springs are available. Select according to valve size and operating conditions. For more details check pressure-reducing pilots' product pages.

Orifice Assembly

Body: Fusion Bonded Epoxy Steel or Stainless Steel

Orifice Plate: Stainless Steel

Notes

- The orifice diameter is calculated for each valve

- Flow Setting Range: (-)15% & (+)25% from predetermined flow

- Orifice assembly adds 20-25 mm to valve length

- The orifice's additional head loss is 0.2 bar

- Recommended continuous flow velocity: 0.3-6.0 m/sec

- Minimum operating pressure: 0.7 bar. For lower pressure requirements consult Deeco.

- Inlet pressure, outlet pressure, and flow rate are required for optimal sizing and cavitation analysis

- When minimum head loss is essential and flow velocity is higher than 1.0 m/sec, consider using the Model 770-j equipped with a pitot tube flow sensor and high-sensitivity flow pilot #7

Technical Specifications

For technical specifications (Flow charts, valve characteristics, dimensions, etc.) - Please refer to the Engineering Data:

Bermad - Model 700 - Sigma EN/ES - Engineering Data

For Spare Parts & Repair Kits - Please refer to the base model:

Due to the wide range of options available and criteria for correct model selection, pricing and configuration are available on application only.

Please consult with Deeco engineers for more information.