| Brand: | Bermad |

| Category: | Control Valves, 400 Series |

| Size Range: | 40-300mm |

| Connection: | 40-80mm - Female Threaded BSP 80-300mm - Flanged |

| Engineering Data: |

Product Description

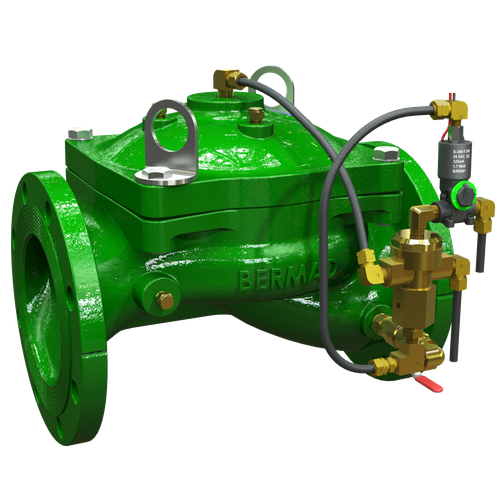

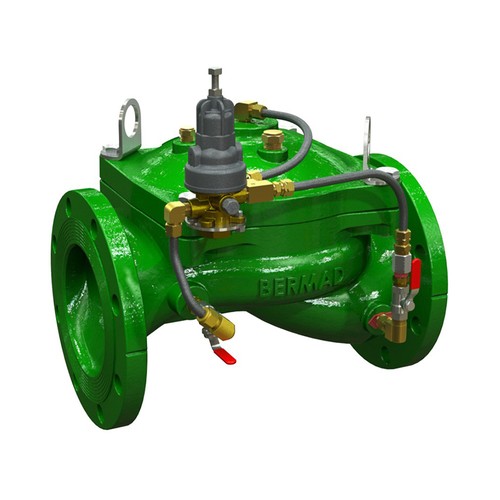

The BERMAD Model 420-55-X 3 Way Pressure Reducing Valve with Solenoid Control is a hydraulically operated, diaphragm-actuated control valve that reduces higher upstream pressure to lower constant downstream pressure regardless of fluctuating demand and opens fully upon line pressure drop. The BERMAD Model IR-420-55-X3 Way Valve opens and shuts in response to an electric signal.

Features and Benefits

- 3-Way Hydraulically Actuated PRV, Electrically Controlled On/Off

- Protects downstream system

- Opens fully upon line pressure drop

- Wide range of pressures and voltages

- Normally Open, Normally Closed, or Last Position

- Advanced Globe Hydro-Efficient Design

- Unobstructed flow path

- Single moving part

- High flow capacity

- Fully Supported & Balanced Diaphragm

- Requires low opening and actuation pressure

- Excellent low-flow regulation performance

- Progressively restrains valve closing

- Prevents diaphragm distortion

- User-Friendly Design

- Easy pressure setting

- Simple in-line inspection and service

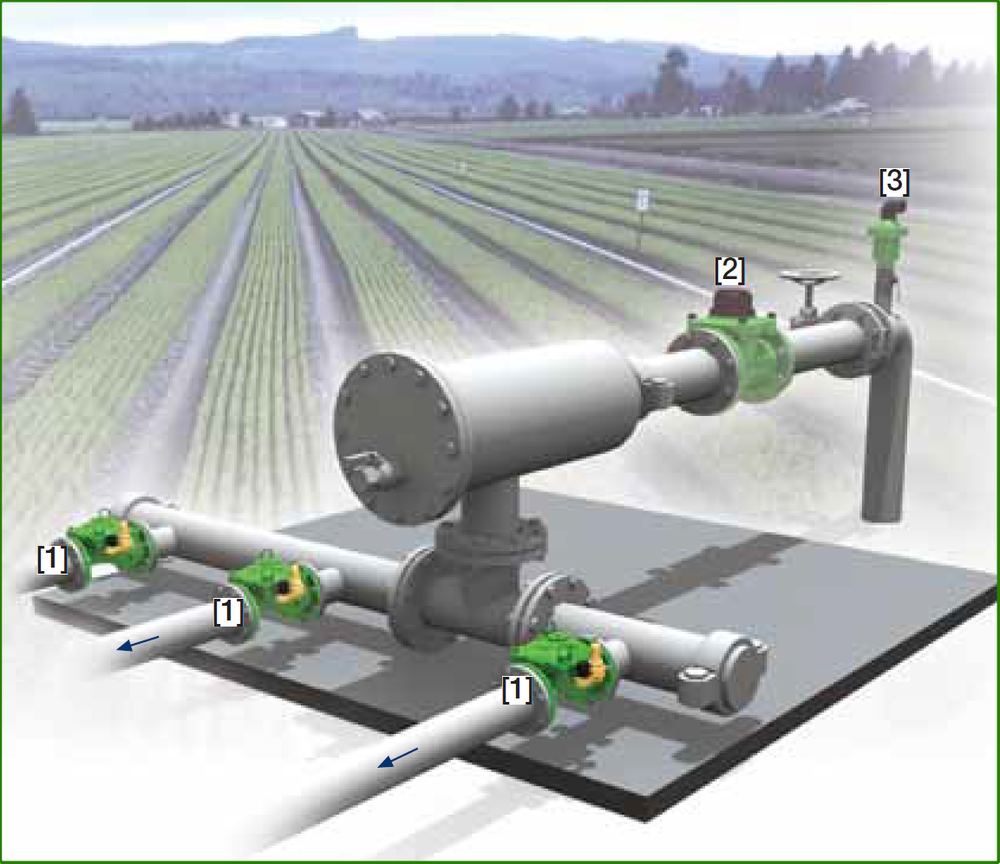

1. BERMAD Model IR-420-55-3 Way opens in response to an electric signal

establishing reduces pressure zone.

2. BERMAD Water Meter Model WPH

3. BERMAD Air Relief Valve Model ARC-A-I-I

Typical Applications

- Pressure Reducing Stations

- Flow and Leakage Reduction

- Systems Subject to Varying Supply Pressure

- Energy Saving Irrigation Systems

- Source and “On Duty” Valves Management

- Pressure Zone Isolation

- Downhill Supply Lines

Technical Data

Operation

The Shuttle Valve [1] hydraulically connects the Solenoid [2] or the Pressure Reducing Pilot (PRP) [3] to the Valve Control Chamber [4]. When the solenoid is closed, the PRP commands the Valve to throttle closed should Downstream Pressure [P2] rise above setting, and to open when [P2] falls below setting. Should line pressure remain below setting - the Valve opens fully. In response to an electric signal, the solenoid switches, directing line pressure through the shuttle valve into the control chamber. This causes the Valve to shut

Materials

Body and Cover

- Polyester Coated Cast or (DN250 and larger) Ductile Iron

Spring

- Stainless Steel

Diaphragm

- Nylon fabric Reinforced NR with rugged insert

Bolts, Studs and Nuts

- Zinc-Cobalt plated Steel

Control Accessories

- Brass

Tubing and Fittings

- Reinforced Plastic and Brass

Pressure Rating

- 16 bar

Operating Pressure Range

- 0.5-16 bar

For lower pressure requirements, consult Deeco.

Setting Range

- 1.5-16 bar

Setting ranges vary according to specific pilot springs. Please consult Deeco.

Solenoid Voltage Range

- 24 VAC, 12VDC, 24 VDC

Other voltages available

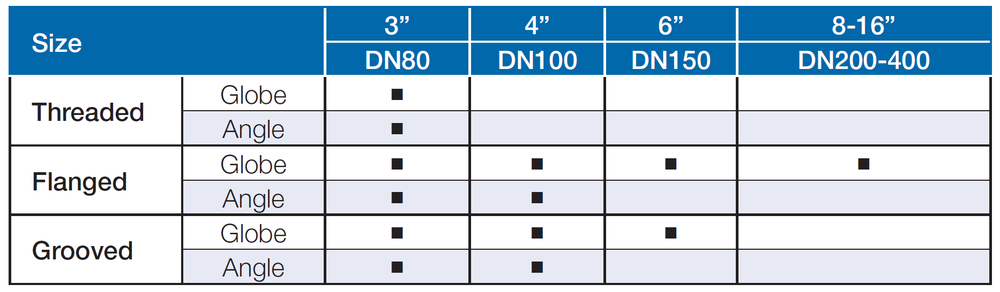

Patterns and Sizes

- Globe: DN80-400

- Angle: DN80-100

End Connections

- 40-80mm - Female Threaded BSP

- 80-400mm - Flanged

Bermad - 420-55-3W - End Connections

Technical Specifications

For technical specifications (Flow charts, valve characteristics, dimensions, etc.) - Please refer to the Engineering Data:

For Spare Parts & Repair Kits - Please refer to the base model:

Due to the wide range of options available and criteria for correct model selection, pricing and configuration are available on application only.

Please consult with Deeco engineers for more information.