| Brand: | Bermad |

| Category: | Control Valves, 400 Series |

| Size Range: | 40-300mm |

| Connection: | 40-80mm - Female Threaded BSP 80-300mm - Flanged |

| Engineering Data: |

Product Description

The BERMAD Model 430-2 Way Pressure Relief/Sustaining Valve is a hydraulically operated, diaphragm-actuated control valve that can fulfill either of two separate functions. When installed in-line, it sustains minimum preset upstream (back) pressure regardless of fluctuating flow or varying downstream pressure. When installed as a relief or circulation valve, it relieves line pressure over preset.

Features and Benefits

- Line Pressure Driven Pressure Relief/Sustaining Valve

- Controls system fill-up

- Sustains upstream line pressure

- Relieves excessive pressure protecting pump and system

- Prioritizes pressure zones

- Advanced Globe Hydro-Efficient Design

- Unobstructed flow path

- Single moving part

- High flow capacity

- Fully Supported & Balanced Diaphragm

- Requires low opening and actuation pressure

- Excellent low-flow regulation performance

- Progressively restrains valve closing

- Prevents diaphragm distortion

- User-Friendly Design

- Easy pressure setting

- Simple in-line inspection and service

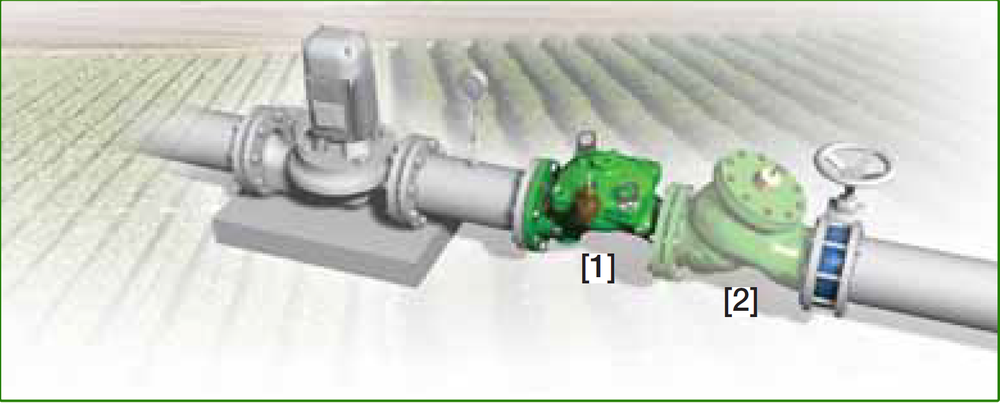

Pressure Sustaining Valve

Pressure Sustaining Valve

1. BERMAD Model IR-430 protects the pump from overload and cavitation, prevents

main line emptying, and controls system fill-up

2. BERMAD Check Valve Model 70N

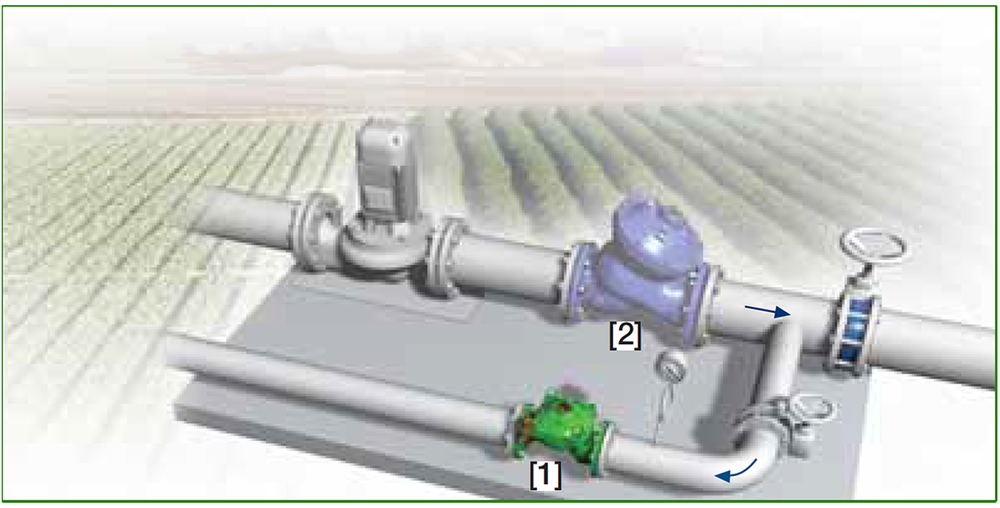

Circulation / Relief Valve

Circulation / Relief Valve

1. BERMAD Model IR-430 safeguards pump minimum flow and relieves excessive

line pressure.

2. BERMAD Active Check Valve Model 740Q

Typical Applications

- Downhill Supply Lines Emptying Prevention

- Pressure Zone Prioritizing

- Line Fill-Up Control

- Pump Overload and Cavitation Protection

- Pump Minimum Flow Safeguard

- Excessive Line Pressure Protection

Technical Data

Operation

The Needle Valve [1] continuously allows line pressure into the Control Chamber [2]. The Pressure Sustaining Pilot [3] senses Upstream Pressure [P1], and throttles when it drops below setting*. Pressure then accumulates in the control chamber causing the Valve to throttle closed maintaining [P1] at the pilot setting, and eventually closing drip-tight. The pilot releases accumulated pressure when [P1] rises above the setting, thereby causing the Valve to modulate open.

* Sustaining (In-Line) Valve Pilot should be set to the minimum system pressure allowed. The relief (Circulation) Valve Pilot should be set slightly above the system working pressure.

Materials

Body and Cover

- Polyester Coated Cast or (DN250 and larger) Ductile Iron

Spring

- Stainless Steel

Diaphragm

- Nylon fabric Reinforced NR with rugged insert

Bolts, Studs and Nuts

- Zinc-Cobalt plated Steel

Control Accessories

- Brass

Tubing and Fittings

- Reinforced Plastic and Brass

Pressure Ratings

- 16 bar

Operating Pressure Range

- 0.5-16 bar

For lower pressure requirements, consult Deeco.

Setting Range

- 1.5-16 bar

Setting ranges vary according to specific pilot springs. Please consult Deeco

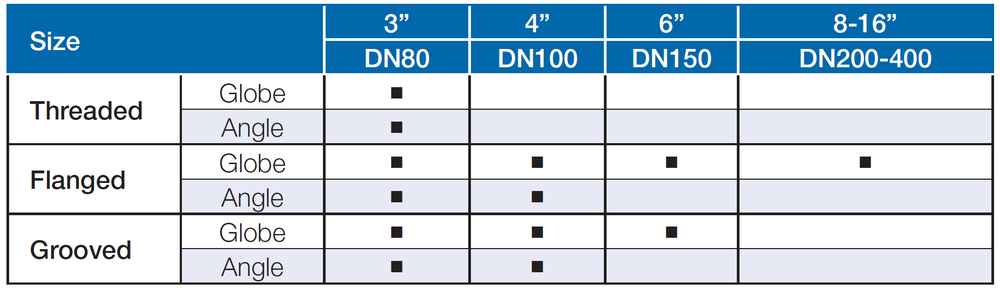

Patterns and Sizes

- Globe: DN80-400

- Angle: DN80-100

End Connections

- 40-80mm - Female Threaded BSP

- 80-400mm - Flanged

Bermad - 430-2W - End Connections

Technical Specifications

For technical specifications (Flow charts, valve characteristics, dimensions, etc.) - Please refer to the Engineering Data:

For Spare Parts & Repair Kits - Please refer to the base model:

Due to the wide range of options available and criteria for correct model selection, pricing and configuration are available on application only.

Please consult with Deeco engineers for more information.