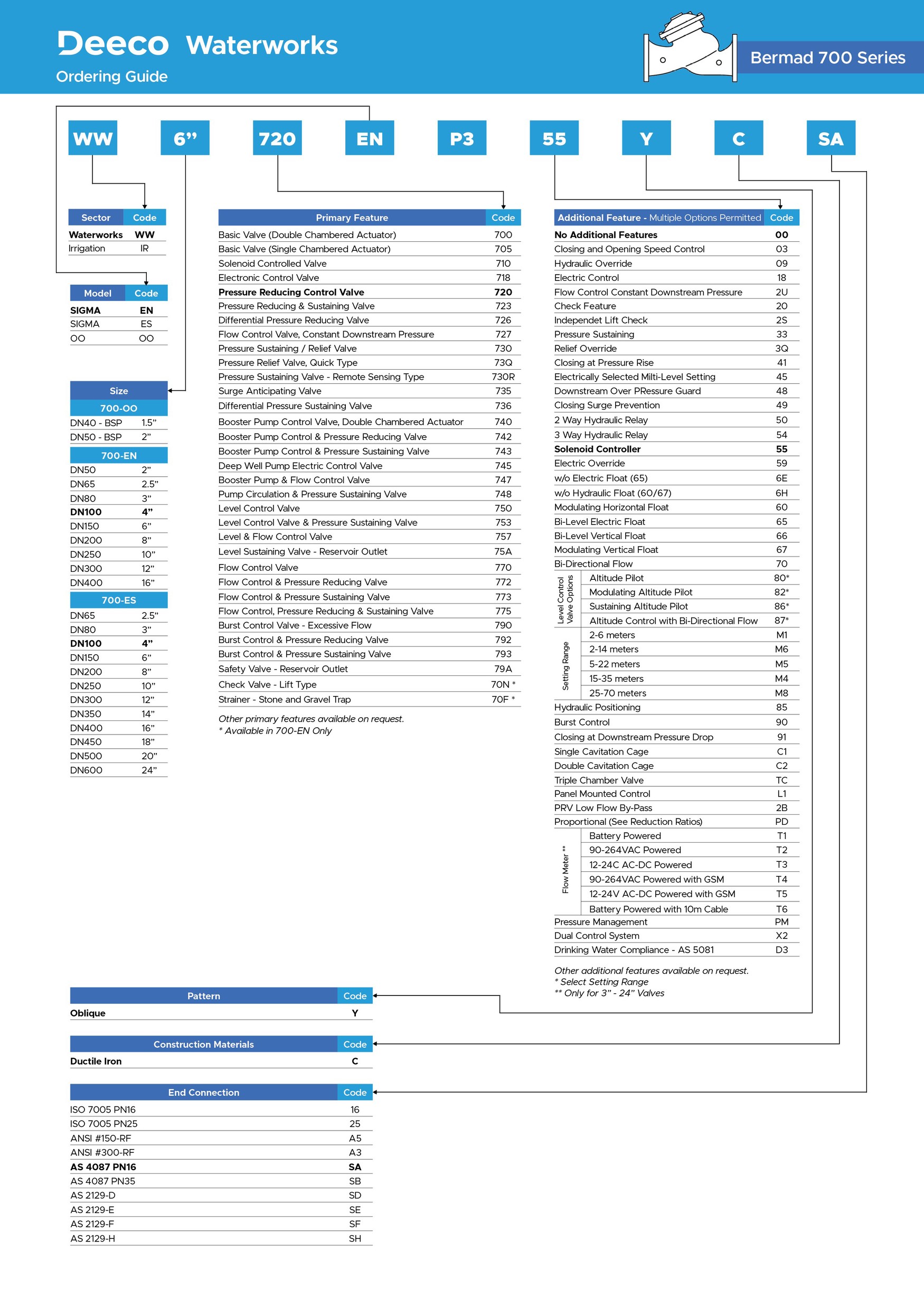

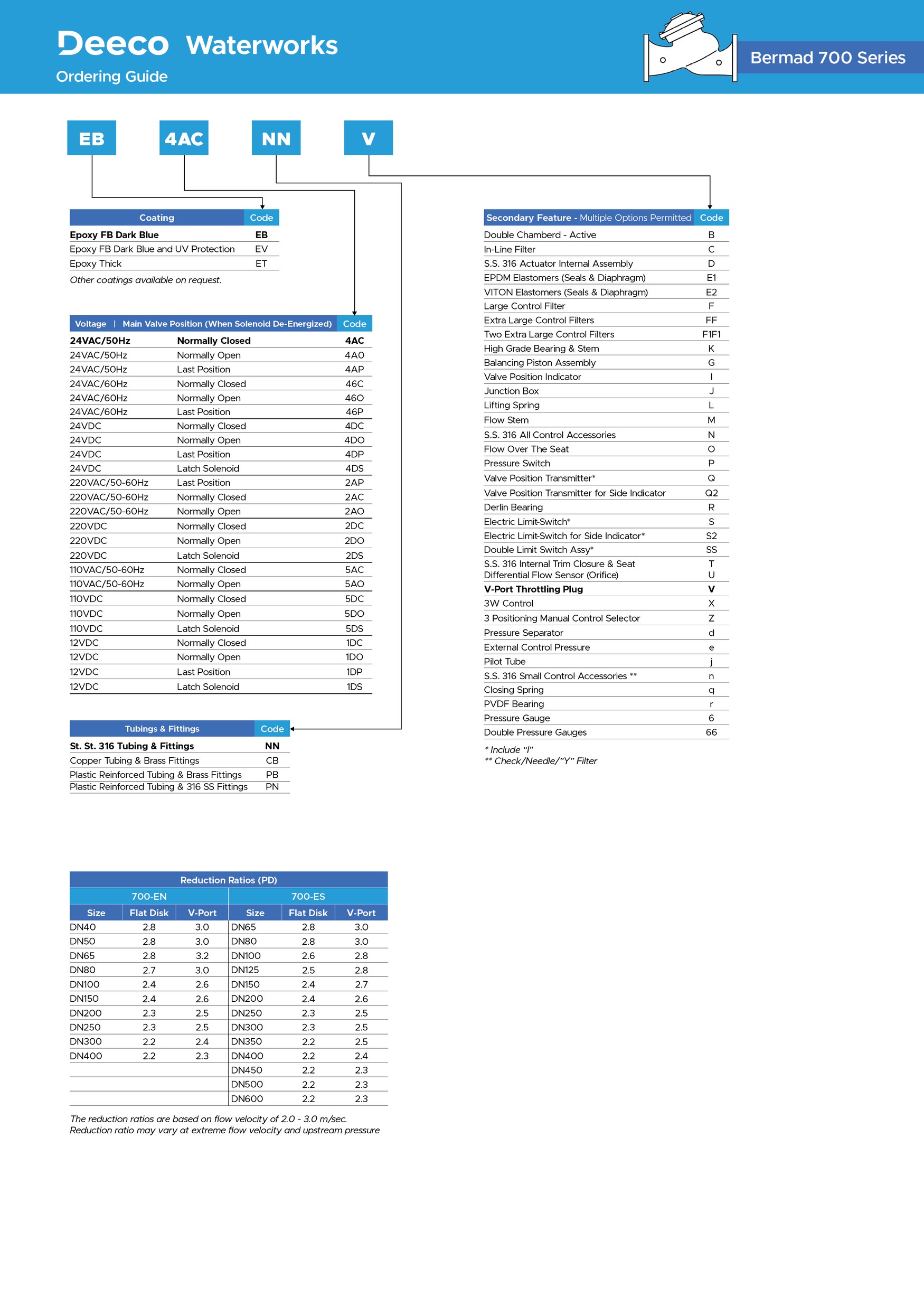

| Brand: | Bermad |

| Category: | Control Valves, 700 Series |

| Size Range: | 50-600mm |

| Connection: | 50 - 80mm - Threaded Female BSPT - Angle Pattern |

| Engineering Data: | |

| Other Options: |

Product Description

Hydraulically operated, diaphragm actuated quick pressure relief valve that relieves excessive system pressure when such pressure rises above a pre-set value. It responds immediately, accurately, and with high repeatability to a rise in system pressure by opening fully. It also provides smooth drip-tight closing. BERMAD 700 series valves are hydraulically operated globe valves available in either standard oblique (Y) or angle (A) pattern design. They have a full-bore hydrodynamic body providing an unobstructed flow path, with a seat assembly and double chamber unitized actuator that can be disassembled from the body as a separate integral unit

Features and Benefits

- Designed to - stand up to the toughest conditions

- Excellent anti-cavitation properties

- Wide flow range

- High stability and accuracy

- Drip tight sealing

- Double chamber design

- Moderated valve reaction

- Protected diaphragm

- Optional operation in very low pressure

- Moderated closing curve

- Flexible design - Easy addition of features

- Obstacle-free flow pass

- V-Port Throttling Plug (Optional) - Very stable at low flow

- Compatible with various standards

- High-quality materials

- ֺ In-line serviceable - Easy maintenance

Major Additional Features

- Flow stem – 73Q-M

- Position indication – 73Q-S

Typical Installation

Bermad - Model-73Q - Typical Installation

Technical Data

Operation

Closed

This drawing refers to 40-200 mm sized valves only. For other sizes please refer to the Model’s IOM.

Open

This drawing refers to 40-200 mm sized valves only. For other sizes please refer to the Model’s IOM.

Main Valve

Valve Patterns: “A” (angle)

Size Range: 50-80mm - Y Pattern 50-600mm

Pressure Rating: 16 bar - with higher pressure options available.

End Connections:

Threaded Female BSPT

Others: Available on request

Temperature Rating: 60°C for cold water applications

Optional Higher temperature: Available on request

Standard Materials:

Body & actuator: Ductile Iron

Bolts, nuts & studs: Stainless Steel

Internals: Stainless Steel, Tin Bronze & Coated Steel

Diaphragm: Fabric-reinforced synthetic rubber

Seals: Synthetic rubber

Coating: Dark blue Fusion bonded epoxy

Control System

Standard Materials:

Accessories: Stainless Steel, Bronze & Brass

Tubing: Stainless Steel or Copper

Fittings: Stainless Steel or Brass

Pilot Standard Materials:

Body: Stainless Steel, Bronze or Brass

Elastomers: Synthetic Rubber

Spring: Stainless Steel

Internals: Stainless Steel

Pilot Options:

Consult Deeco.

Notes

- Main pipe diameter, pressure rating, flow rate and relief pressure are required for optimal sizing

- Recommended continuous flow velocity: 0.3-15 m /sec.

Technical Specifications

For technical specifications (Flow charts, valve characteristics, dimensions, etc.) - Please refer to the Engineering Data:

Bermad - Model 700 - Sigma EN/ES - Engineering Data

For Spare Parts & Repair Kits - Please refer to the base model:

Due to the wide range of options available and criteria for correct model selection, pricing and configuration are available on application only.

Please consult with Deeco engineers for more information.